- home

-

Products

- Products

- Metrici LPR

- Metrici LPR Parking Module

- Metrici LPR Toll Station Module

- Metrici LPR Weighing Module

- Metrici PPD

- Metrici Area Counter

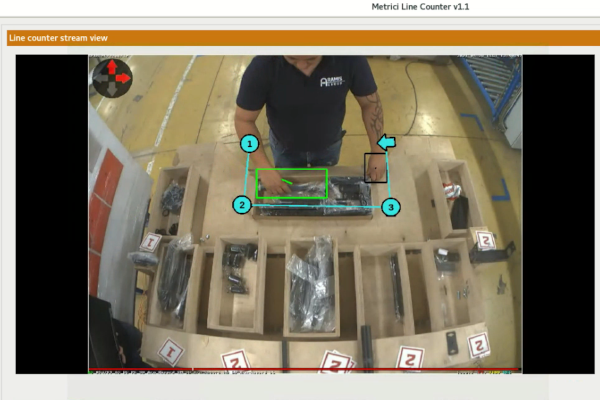

- Metrici Line Counter

- Metrici Thermal Analyzer

- Metrici Custom Applications

- Metrici Car Kit

- Metrici Server Systems

- Metrici Observer Radar

- Metrici LED Display

- Metrici MultiController

- Metrici LAN Controller

- Benefits

- case studies

- Resources

- news

- videos

- Contact

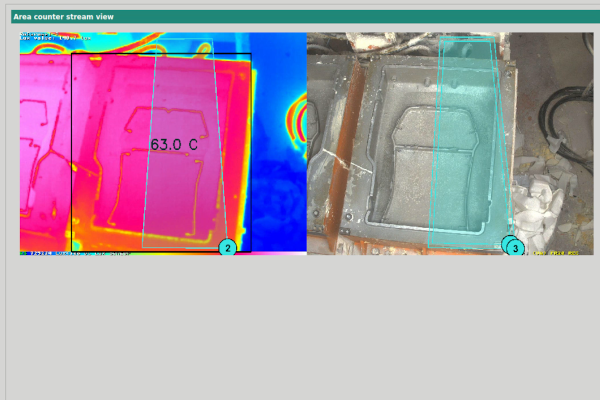

Area Counter and Thermal Analyzer for custom projects

Creative inspire from other works

The Metrici Area Counter engine and the thermal analyzer are working together to generate some useful insights in some factories around the world.

First built as a tool for counting people and cars in smart city development projects, Area Counter managed to extend higher on its own, but also in collaboration with other Metrici engines.

This solution is used in industrial projects as a tool to detect and recognize different objects on production lines.

Automotive industry

First project to present is a car seat manufacturer. The work is a complex one, as multiple analysis are made for each object. First of all, Metrici detects what kind of object, in our case what kind of seat it is (namely for what car model) from a list of over 30 classes. Secondly, it verifies that it is properly set for final production: checks for special points on that specific mold model where magnets and wires should be placed. If anything is missing, it raises an alert and stops the production, as it would result a defective product.

Finally, another engine, Thermal Analyzer, is checking the mold’s temperature, which depending of its class should have a certain value. If that value is not reached, another alarm is set to stop the production and not to pour foam on the mold to form the seat.

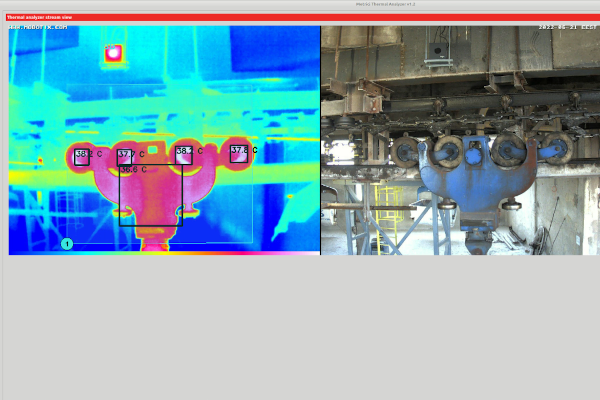

Chemical plant

Another case study refers to one production company in Bulgaria in chemical industry.

This is where also two Metrici detection engines are used for the moment.

In a first alignment, using also Area Counter, Metrici is searching for transport carriages, detects them and checks if they are in the right position and not upside down, after a certain control point.

Secondly, it checks with Thermal Analyzer on a thermal camera what is the temperature of the bearings. If it is too high (above a certain value that can be set in the Interface ) an alarm is raised to stop the wagons at it is danger of a malfunction which generates losses.

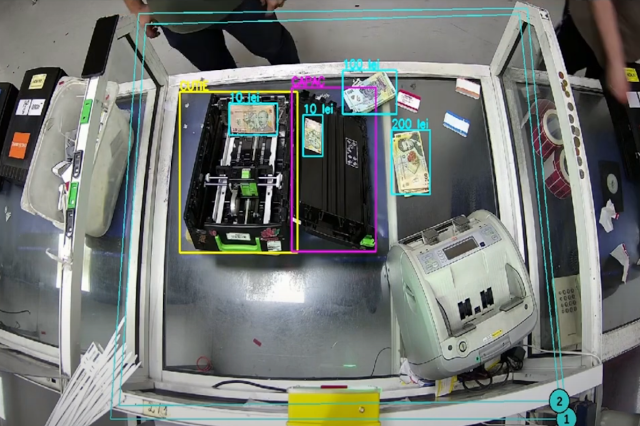

In fact these are not the only examples. As seen before, Area Counter can be used in many ways in industrial projects. It was implemented as such on many production lines, in different scenarios, where Metrici checks number and quality of products, raising alarms when defects show or when is a mismatch. For each project, Metrici usually does a dedicated AI training for that specific environment so as to ensure 100 percent accuracy.

Where else?

Between Metrici successful projects we can find a brick factory where we look for defective products along the the three stages of production. Also a car component factory where an automated painting is done on some parts and Metrici checks the production lines delivers the right pieces on the right tray so the robot painting arm can know what distance to take and what objects is about to finish. Also, as an alert in some robotized factory where Metrici checks if the human personnel is mandatory to wear safety equipment and the examples could go on. Similar implementations were used with Line Counter detection engine. As seen in the first example photo from above, this is used in a packaging unit in a factory where Metrici keeps count on how many items are boxed for each product raising alerts when something is missing. In fact , the solution are so versatile that could fit in any scenario, where visual inspection is required and can be done with a powerful camera and Metrici accurate detection capabilities.

For example, Area Counter or Line Counter can be used to detect

- Number of objects on the production line

- Defective objects in the area

- Mismatch objects in an area

- Productivity rate

- Calculate effectiveness

- Person in a restricted area

- Alert when certain events occur

- Number bigger than..

That will finally lead to